Table of Contents

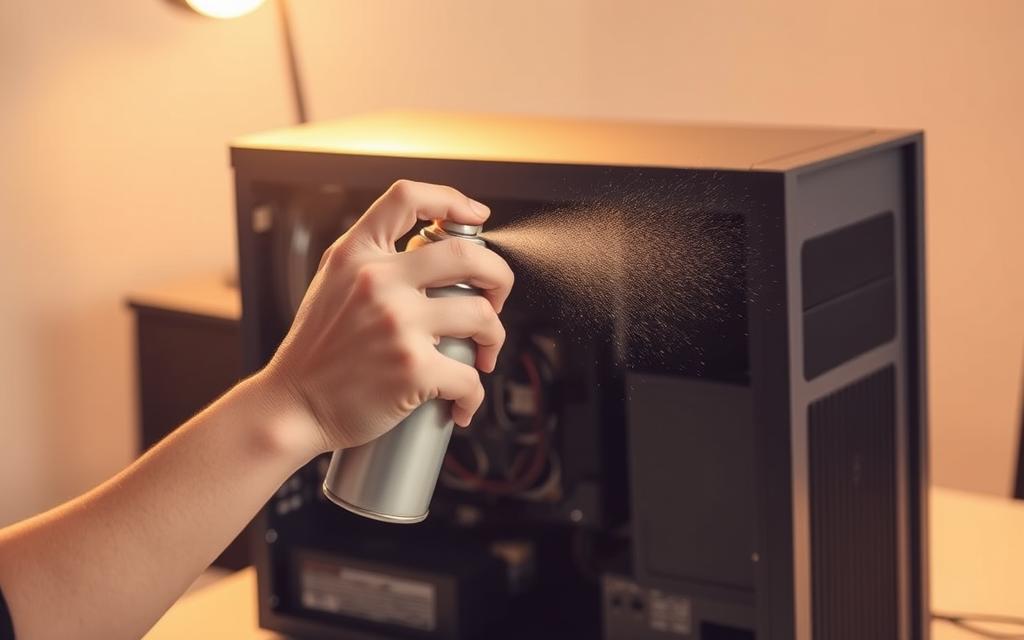

Keeping electronics dust-free is essential for performance. Many rely on compressed air for quick cleaning. But is it safe to power on devices immediately?

Why Timing Matters

This cleaning method blows away debris from keyboards and internal parts. However, moisture or residue might linger. Experts recommend brief waiting periods for different components.

Printers and delicate circuits need extra care. Rushing could cause short circuits or damage. Always check manufacturer guidelines for specific models.

Proper technique prevents static buildup and component stress. Let’s explore safe practices for maintaining your tech with compressed air solutions.

Understanding the Risks of Compressed Air Cleaning

Many overlook hidden dangers when cleaning electronics with compressed air. While effective for dust removal, improper techniques can harm components or worsen debris buildup.

Liquid Refrigerant and Component Damage

Tilting the canister releases liquid refrigerant instead of air. This cold foam acts as a solvent, stripping protective coatings from parts like motherboards. A 2021 Office Depot® incident showed how tilted sprays caused permanent damage to connector pins.

Experts recommend holding cans upright. This prevents accidental discharge of harmful chemicals. Always check labels for safety warnings.

Static Electricity and Dust Redistribution

High-pressure bursts create static charges. This attracts dust to sensitive circuits, counteracting cleaning efforts. Fans and vents often collect relocated debris, worsening thermal issues.

Short bursts from 6 inches away reduce static buildup. Avoid continuous spraying on one area to prevent overheating.

How Long to Wait Before Using Your Computer After Compressed Air

Proper timing ensures electronics stay safe during cleaning. Rushing to power on devices risks damage from residual moisture or displaced dust. Follow these guidelines to protect your components.

Drying Time for Liquid Exposure

Accidental liquid discharge requires 5–10 minutes to evaporate. Tilting the can sprays refrigerant, which can strip coatings. If this occurs, power off the device immediately and let it dry horizontally.

Component-Specific Waiting Periods

Keyboards need 15 minutes after cleaning. Internal parts like CPUs and GPUs demand 30 minutes to avoid thermal stress. Fans require extra care—bearing lubrication can degrade if moisture lingers.

Metal parts dry faster than plastics. Check for visible residue before reconnecting power. For significant spills, wait 24 hours and consult a technician.

Best Practices for Safe Compressed Air Use

Effective cleaning with compressed air requires precision and care. Minor mistakes can push dust deeper or harm fragile components. Follow these methods to maintain peak performance.

Mastering Can Positioning

Hold the can upright at a 45-degree angle. Tilting risks liquid discharge, which damages parts. Keep the nozzle 1–3 inches from surfaces for controlled airflow.

Use 2-second bursts with pauses between sprays. This prevents moisture buildup and static charges. Target vents first to stop dust from recirculating.

Focus on High-Risk Areas

Fans and keyboards collect the most debris. Clean fans while holding blades still to avoid bearing damage. For keyboards, invert them and spray at an angle to dislodge particles.

- Avoid prolonged spraying on plastic—it can warp or crack.

- Prioritize vents to improve airflow and cooling.

- Inspect for residue before reassembling devices.

Post-Cleaning Checks Before Powering On

Before turning on your device, thorough post-cleaning checks prevent avoidable damage. Safety protocols don’t end with spraying—verification is critical for component longevity.

Inspecting for Moisture Residue

Use a flashlight to scan for glossy spots on parts. Isopropyl alcohol (70%+) dissolves stubborn residue without harming circuits. Focus on crevices near fans and vents where dust clings.

- Check for condensation on metal surfaces—wipe immediately.

- Plastic components tolerate slight dampness but should feel dry.

- Let the device air-dry for 5 minutes if unsure.

Verifying Component Security

Loose connections cause 30% of post-cleaning failures. Gently tug cables to confirm snug fits. Reseat RAM and GPUs by aligning notches and pressing firmly until clicks are heard.

“Over-tightening screws cracks PCB layers. Finger-tight plus a quarter-turn is ideal for most components.”

Run a multimeter on power supply pins if the computer previously shorted. No continuity between pins ensures safety.

Conclusion

Smart maintenance keeps devices running smoothly for years. Proper cleaning with compressed air prevents dust buildup and extends lifespan by 3–5 years.

Always wait 15–30 minutes before powering on. Quarterly sessions boost speed and save money on replacements. Hold cans upright to avoid liquid spills.

Follow these steps for peak performance. Your computer will thank you.

FAQ

Can I turn on my PC immediately after cleaning with compressed air?

No. Wait at least 5–10 minutes to ensure any residual liquid evaporates and dust settles. Powering on too soon risks short circuits or component failure.

Does compressed air damage computer parts?

Yes, if misused. Liquid refrigerant from the can may condense on components, while high-pressure sprays can dislodge fragile parts like capacitors or fan blades.

How do I safely clean fans with compressed air?

Hold fans stationary with a finger to prevent overspinning, and spray in short bursts at a 45-degree angle. Avoid tilting the can to minimize liquid discharge.

Why does my keyboard act strange after compressed air cleaning?

Moisture or displaced dust under keys can cause malfunctions. Wait 15+ minutes before use, and gently shake the keyboard to dislodge debris.

Are there areas I should avoid spraying with compressed air?

Yes. Never direct airflow at open vents with spinning drives, exposed circuit boards, or loose cables. Focus on non-sensitive areas like case vents and fan blades.

How often should I clean my computer with compressed air?

Every 3–6 months for home PCs, or monthly in dusty environments. Overuse increases static electricity risks—balance cleanliness with minimal component exposure.