Table of Contents

Many people are surprised to learn that their everyday electronic devices, including computers, contain small amounts of precious metals. These hidden treasures, particularly within printed circuit boards, hold both monetary and environmental value.

With global e-waste reaching 50 million tons annually, only 12.5% gets properly recycled. This represents a significant loss, as one tonne of discarded electronics can yield far more recoverable material than traditional mining operations.

The presence of valuable materials in outdated technology creates opportunities for resource recovery. According to Interesting Engineering, industrial equipment sometimes contains surprisingly high concentrations.

This article explores the reality behind reclaiming these materials. We’ll examine actual quantities, practical recovery methods, and why responsible recycling matters for our environment.

Introduction: The Hidden Gold in Your Electronics

Modern technology conceals a surprising source of precious materials. Discarded electronic devices contain measurable quantities of recoverable elements, particularly within their circuit boards.

The United States generates 11 million tons of e-waste annually. Shockingly, one tonne of this waste yields 40-800 times more precious metals than traditional mining operations.

Consider these key comparisons:

- Traditional mining: Requires processing 2-3 tons of ore for 1 gram of gold

- Urban mining: Recovers the same amount from just 41 mobile phones

An average desktop contains $9-$12 worth of recoverable gold. While this seems modest, multiplied across millions of obsolete computers, the cumulative value becomes significant.

Improper disposal creates environmental hazards. Heavy metals can leach into soil and water when electronics reach landfills. Responsible recycling prevents this while recovering valuable resources.

Gold distribution varies across components. Later sections will detail which parts offer the highest concentrations and why manufacturers use these precious metals in specific applications.

Why Is Gold Used in Computers and Electronics?

Electronics manufacturers select materials based on specific technical demands. Gold stands out for its unmatched reliability in critical components, despite higher costs compared to alternatives.

Gold’s Superior Conductivity and Corrosion Resistance

With 44.6 million siemens per meter (MS/m) conductivity, gold trails only slightly behind copper (59.6 MS/m). However, its immunity to oxidation ensures stable performance in humid or high-temperature environments.

NASA leverages this trait for satellite circuit boards and astronaut visor coatings. Gold’s reflectivity also shields spacecraft from solar radiation.

Gold vs. Other Precious Metals in Electronics

Silver offers higher conductivity but tarnishes easily. Copper is affordable but requires protective coatings. Precious metals like gold strike a balance:

- Durability: Gold-plated connectors withstand 10,000+ insertion cycles.

- Precision: Ideal for microelectronics due to consistent electron flow.

- Industry demand: Electronics consume ~300 tonnes annually.

Thin gold plating (0.1–2.5 microns) optimizes cost while preserving performance. This technique dominates in high-end components like CPU pins and memory contacts.

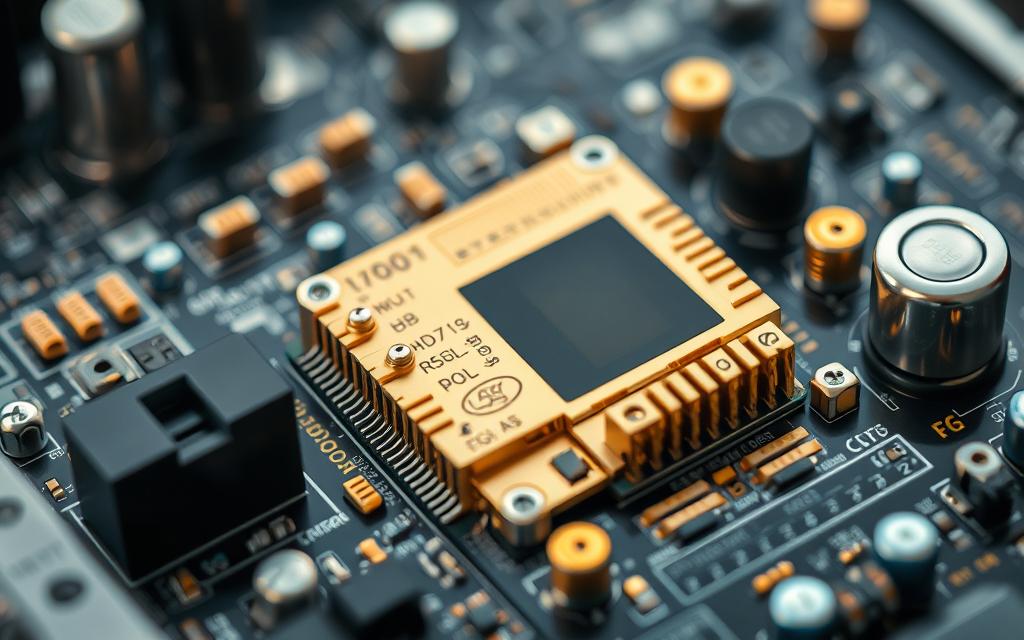

Key Computer Components That Contain Gold

Hidden within common electronics lie traces of valuable materials waiting to be recovered. Specific components house these precious elements, particularly in older or high-performance devices.

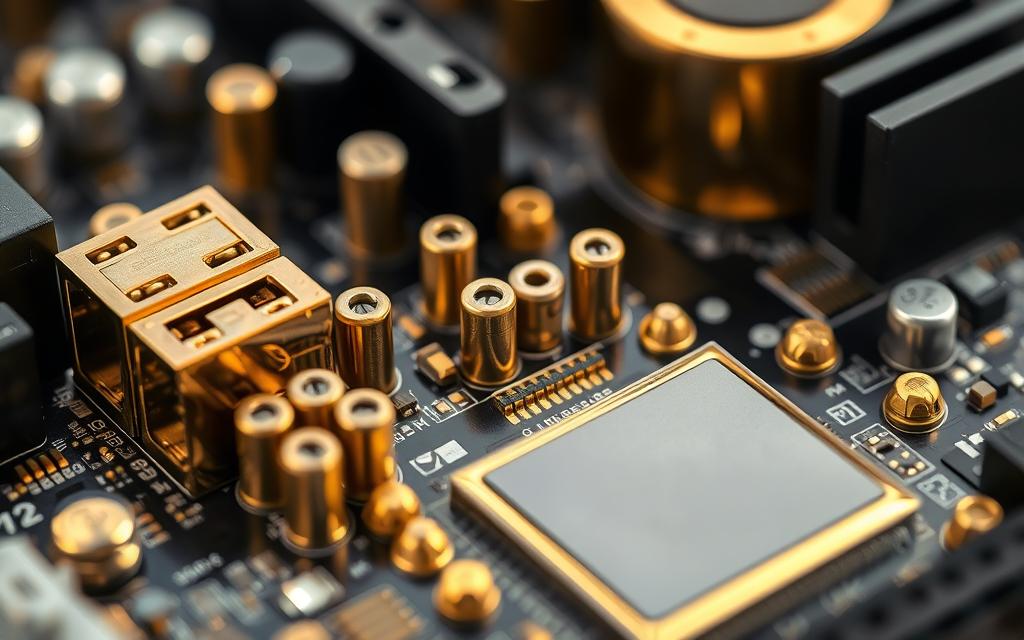

Motherboards and Printed Circuit Boards

Printed circuit boards (PCBs) are gold hotspots. Thin layers coat tracers, edge connectors, and IC bond wires. Vintage motherboards often have thicker plating than modern ones.

Look for yellowish sheens on PCI slots or RAM sockets. Surface-mount devices (SMDs) typically contain less than through-hole parts due to miniaturization.

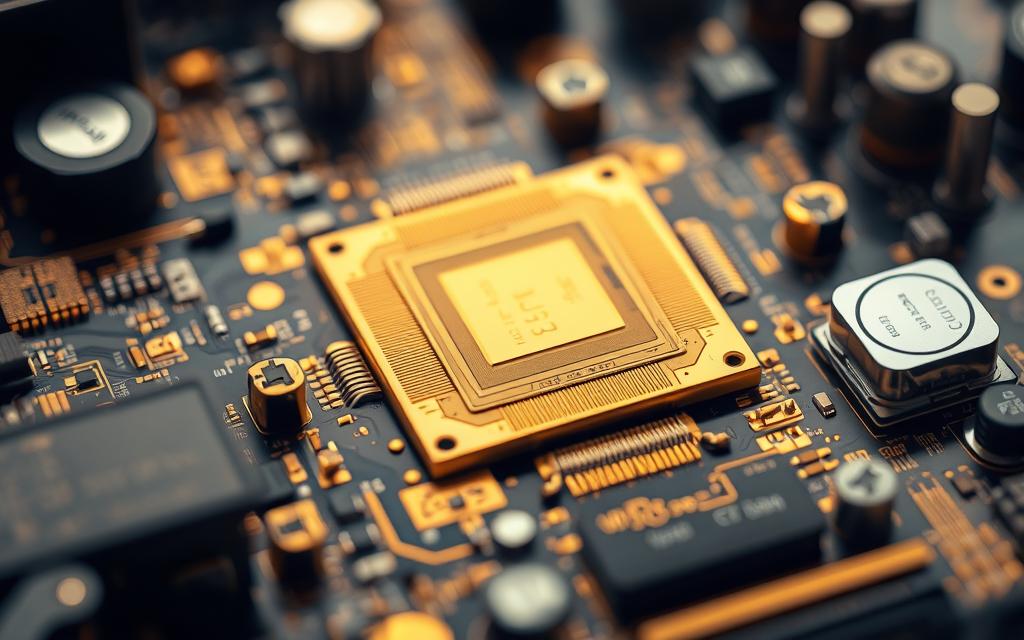

Central Processing Units (CPUs)

CPUs pack hundreds of gold-plated pins for reliable conductivity. Older models, like Intel Pentium Pros, are prized for their higher content. Modern chips use thinner layers but still contribute to recoverable totals.

RAM Chips and Other Peripherals

RAM modules vary by era—pre-DDR3 often has more gold contacts. GPUs, hard drive flex cables, and even some capacitors hold trace amounts. Visually, shiny gold plating tarnishes less than copper or silver.

Key identifiers:

- Gold-colored edges on expansion slots

- Non-magnetic contacts (gold doesn’t stick to magnets)

- Manufacturer markings on high-value computer chips

How Much Gold Is in an Average Computer?

Not all computers are created equal when it comes to precious metal content. The amount varies significantly between device types and manufacturing eras. Understanding these differences helps assess recycling potential.

Desktop vs. Laptop Gold Content

Full-sized desktops typically contain twice the recoverable material of portable devices. A standard tower holds about 0.2 grams ($12 value), while laptops average just 0.1 grams ($6).

This discrepancy stems from design differences:

- Expansion slots: Desktops have more gold-plated connectors

- Component density: Laptops use miniaturized, gold-light parts

- Cooling requirements: Desktops tolerate thicker metal layers

Comparing Gold in Modern vs. Older Computers

1980s-era devices used approximately 10 times more precious metals than current models. An IBM 3081 mainframe processor contained 0.028 grams, while modern Ryzen CPUs have just 0.0005 grams.

This reduction stems from:

- Improved manufacturing techniques

- Thinner plating layers

- Alternative materials adoption

| Component | Gold Distribution | 1980s (grams) | 2020s (grams) |

|---|---|---|---|

| Connectors | 45% | 0.012 | 0.001 |

| Integrated Circuits | 30% | 0.008 | 0.0003 |

| Circuit Boards | 25% | 0.007 | 0.0001 |

Note: Industrial and medical equipment often defy these trends. Some specialized machines contain over 56 grams due to extreme reliability requirements.

Other Precious Metals Found in Computers

Beyond gold, computers harbor several other valuable metals essential for modern electronics. These materials ensure performance, durability, and miniaturization across board components.

Silver, Palladium, and Copper in Electronics

Silver outperforms gold in conductivity but requires anti-tarnish coatings. It’s commonly found in:

- Keyboard membranes (0.05g per device)

- Power supply units (PSUs)

Palladium appears in multilayer ceramic capacitors (MLCCs), crucial for signal filtering. A single capacitor holds 0.0002g, but millions are used annually.

Rare Metals in Hard Drives and Components

Hard drives store value beyond data. Platters often contain platinum-group metals, while spindle motors use neodymium magnets (1g per HDD).

Tantalum capacitors, vital for voltage regulation, hold 0.0005g Ta each. Displays incorporate rare earths like europium for color vibrancy.

| Metal | Component | Average Quantity | Scrap Value (per device) |

|---|---|---|---|

| Silver | PSUs, switches | 0.3g | $0.18 |

| Palladium | MLCC capacitors | 0.001g | $0.03 |

| Neodymium | HDD motors | 1g | $0.12 |

Note: Values fluctuate with market prices. Industrial servers may contain 5× these amounts.

The Global E-Waste Problem and Gold Recycling

Electronic waste has become one of the fastest-growing pollution sources worldwide. Over 70% of discarded devices end up in developing nations, where informal recycling practices amplify health and environmental risks.

Statistics on Recovery and Lost Potential

The industry recovers only 12.5% of global e-waste annually. Yet, one tonne of circuit boards yields up to 800 times more precious metals than mined ore. Urban mining could offset 30% of virgin material demand if scaled properly.

Key disparities exist between economies:

- Formal systems: Use regulated smelters like Umicore, capturing 95% of metals.

- Informal operations: Often burn cables, releasing dioxins with 170x cancer risk.

Hidden Costs of Improper Disposal

Beryllium in sockets and mercury in screens leach into groundwater when dumped. The Basel Convention now restricts e-waste exports, but enforcement remains inconsistent.

“Burning just five smartphones releases enough toxins to pollute an Olympic-sized pool.”

Urban mining emits 90% less CO₂ than traditional extraction. Companies like Boliden now process 120,000 tons of scrap electronics yearly, proving sustainable models exist.

Is Extracting Gold from Computers Worth It?

Recovering precious metals from electronics presents both opportunities and challenges. The feasibility depends on scale, methods, and market conditions. Industrial operations achieve far better results than individual efforts.

Small-Scale vs. Industrial Recycling

Professional facilities recover up to 95% of available metals. They use advanced techniques like smelting and electrolysis. Home methods typically capture only 40% due to equipment limitations.

Key differences:

- Volume: Processing 10kg of circuit boards yields better returns than single devices

- Safety: Industrial plants have proper ventilation and waste management

- Regulations: Large operations comply with environmental standards

Costs and Challenges of Gold Extraction

The aqua regia process costs approximately $5.50 per gram recovered. This includes chemicals like nitric and hydrochloric acid. Additional expenses come from safety gear and permits.

Important considerations:

- PPE requirements: Fume hoods, respirators, and chemical-resistant gloves

- Legal aspects: Cyanide processes need special permits in most states

- Market fluctuations: Gold prices directly impact profitability

“Professional refiners recover nearly all precious metals, while hobbyists lose over half through inefficiency.”

For those interested in specific components, older CPUs like the Pentium Pro contain higher concentrations. However, the processing costs often outweigh the scrap value for small quantities.

| Method | Efficiency | Cost per Gram |

|---|---|---|

| Industrial | 95% | $3.20 |

| DIY Chemical | 40% | $5.50 |

| Mechanical | 25% | $2.80 |

Environmental responsibility should factor into decisions. Proper recycling prevents toxins from entering ecosystems while recovering valuable resources.

How to Extract Gold from Computer Parts Safely

Safety should always come first when attempting to reclaim valuable materials from computer components. Professional refiners use controlled environments, while hobbyists must take extra precautions.

Comparing Chemical and Non-Chemical Methods

Different approaches yield varying results when recovering precious metals. Chemical methods generally offer higher recovery rates but require strict safety measures.

- Acid baths: Aqua regia achieves 92% recovery but demands fume hoods

- Vinegar-peroxide: Safer alternative with 78% efficiency

- Mechanical separation: Crushing and sifting yields 25-40%

Industrial operations sometimes use cyanide leaching, which requires special permits. Mercury amalgamation should always be avoided due to extreme toxicity.

Manual Extraction Process in Six Steps

Follow this basic procedure to find gold in old electronics safely:

- Collect necessary tools: ceramic crucible, borax flux, graphite mold

- Identify gold-rich parts like pins and connector contacts

- Remove components using proper desoldering techniques

- Process materials in well-ventilated area with PPE

- Use borax to lower melting point to 1064°C

- Pour molten material into mold for final collection

“Proper protective equipment prevents 90% of common refining accidents.”

Always work in small batches and have neutralizing agents available. Consider professional refining services for large quantities or complex components.

How Much Gold Is in Other Electronics?

Various electronics beyond computers hold recoverable precious metals. These materials appear in different concentrations depending on device type and manufacturing era.

Mobile Devices and Compact Electronics

Smartphones pack valuable materials into tiny spaces. An iPhone typically contains 0.034 grams ($2.10 worth) primarily in:

- SIM card contacts (0.005g each)

- Camera module connectors

- Logic board plating

Tablets follow similar patterns but with slightly higher totals due to larger circuit boards. High-end models often use more precious metals for durability.

Displays and Peripheral Equipment

Older CRT televisions contain minute amounts in deflection yokes (0.0003g). Modern displays use thinner layers but spread them across more components:

- OLED screens have gold in driver ICs

- LED backlights use silver instead

- Touchscreen controllers contain palladium

Printer cartridges surprise many with their chip gold content. Industrial printers often have higher concentrations than consumer models.

| Device Type | Gold Content (grams) | Key Locations |

|---|---|---|

| Enterprise servers | 0.5-2.0 | Backplane connectors, memory slots |

| Smartphones | 0.02-0.04 | SIM trays, board contacts |

| CRT monitors | 0.0002-0.0005 | Yoke windings, control boards |

| Inkjet printers | 0.001-0.003 | Cartridge chips, sensor arrays |

Device age and manufacturer affect metal distribution. Military and medical electronic devices often exceed consumer-grade concentrations by 5-10 times.

Alternatives to Gold in Future Electronics

Material scientists are actively seeking substitutes for precious metals in circuitry. The industry faces dual pressures: reducing costs while maintaining reliability in components. These efforts could transform how we manufacture everything from smartphones to satellites.

Industry Efforts to Reduce Gold Dependency

Major manufacturers are testing innovative approaches to minimize precious metal use. IBM’s polymer solder reduces gold requirements by 80% in computer chips. These polymers maintain conductivity while using nanometer-thin layers of alternative materials.

Key developments include:

- Graphene interconnects showing 20% lower resistance than gold

- Self-assembling molecular wires for microscopic circuits

- Bio-based conductors derived from plant proteins

Emerging Materials and Technologies

Cutting-edge research focuses on carbon-based solutions for printed circuit applications. Carbon nanotubes now fill vias more efficiently than traditional plating methods. Their tubular structure provides multiple conduction paths within microscopic spaces.

Other promising alternatives:

- PEDOT:PSS polymers for flexible electronics

- Atomic layer deposition (ALD) of ruthenium coatings

- Self-healing circuits using liquid metal alloys

“By 2040, we expect alternative materials to displace 40% of gold usage in standard electronics.”

These innovations promise more sustainable production without compromising performance. Future devices may use hybrid systems combining multiple technologies at critical contacts and junctions.

Conclusion: The Real Value of Gold in Your Old Computer

Discarded electronics hold hidden value beyond their original purpose. While one old computer may yield modest amounts, collective recycling of 1 million devices recovers roughly 200kg of gold—enough to mint 8,000 coins.

Precious metals in e-waste demand responsible handling. Certified recyclers (R2/RIOS compliant) safely extract materials while preventing toxins from leaching into ecosystems. DIY methods often waste resources and pose health risks.

Prioritize professional recycling to maximize recovery rates. Facilities like E-Stewards or Umicore specialize in refining gold from electronics efficiently. Their processes capture 95% of available metals versus 40% in home setups.

Join the movement to curb e-waste. Locate authorized drop-off points via Earth911’s directory. Together, we can transform outdated tech into sustainable resources—one device at a time.

FAQ

What electronic components contain the most gold?

Printed circuit boards, CPUs, and RAM chips typically have the highest concentration due to gold-plated contacts and connectors.

Can you extract precious metals from hard drives?

Yes, hard drives contain small amounts of gold, silver, and palladium in their circuit boards and connectors.

Is recycling e-waste for gold profitable?

Industrial-scale recycling can be profitable, but small-scale extraction often isn’t worth the time and chemical costs.

How does gold content in modern computers compare to older models?

Older devices generally contain more precious metals as manufacturers now use thinner layers and alternative materials.

What safety precautions are needed for gold extraction?

Proper ventilation, protective gear, and approved chemical disposal methods are essential when handling acids and solvents.

Which household electronics contain the second-highest gold content after computers?

Smartphones and tablets have significant gold concentrations in their circuit boards and connectors.

Are there environmental concerns with gold extraction from electronics?

Improper methods can release toxic chemicals, making professional recycling the safer choice for the environment.

What alternatives to gold are being developed for electronics?

Researchers are testing copper alloys, graphene, and conductive polymers as potential substitutes in future devices.