Table of Contents

Welcome to our comprehensive guide to computer-aided design (CAD), a powerful tool used by engineers and designers to create design simulations of real-world goods and products. CAD enables designers to optimize and perfect their designs in a digital environment before moving on to manufacturing. In this article, we will delve into the fundamentals of CAD, including its use in 2D and 3D design simulations.

Computer-aided design (CAD) is the process of digitally creating design simulations of real-world goods and products in 2D or 3D. With CAD, designers can bring their ideas to life with scale, precision, and physics properties. This technology revolutionized the traditional engineering and design methods, replacing manual drafting and allowing for more efficient design iterations.

CAD is widely used in various industries, including architecture, automotive, aerospace, and manufacturing. It is a collaborative tool that enables engineers and designers to work together and streamline the design process. By creating detailed and accurate digital models, CAD software facilitates communication, visualizes concepts, and optimizes designs.

In the next sections, we will explore the different aspects of CAD, including its functionality, types, and benefits. We will also provide insights into popular CAD software options and factors to consider when choosing the right CAD solution for your needs. Whether you are a seasoned designer or just starting your CAD journey, this guide will equip you with the knowledge and resources to leverage the power of computer-aided design effectively.

What is CAD (Computer-Aided Design)?

CAD, short for computer-aided design, is the process of digitally creating design simulations of real-world goods and products. It enables designers to develop precise 2D or 3D representations, incorporating scale, accuracy, and physics properties. By utilizing CAD tools, designers can optimize and refine their designs before the manufacturing phase, saving time and resources.

CAD is widely used in various industries and is often referred to as computer-aided design and drafting (CADD). It has revolutionized the traditional manual drafting methods, replacing them with advanced digital techniques. With its collaborative nature, CAD enables designers and engineers to work seamlessly together, streamlining the design process.

“CAD allows designers to shift from conceptualization to visualization, empowering them to create intricate and detailed designs with ease.”

By leveraging CAD software, designers can construct both 2D drawings and detailed 3D models. These digital representations can be easily shared, reviewed, simulated, and modified, facilitating iterative design processes. CAD software has become an indispensable tool in engineering and design, enabling professionals to bring their ideas to life with accuracy and efficiency.

With the advent of CAD, manual drafting limitations have been overcome. CAD provides a wealth of features, including powerful tools for measuring, scaling, and rendering, making it an ideal choice for designers working on complex projects. It has transformed industries such as architecture, automotive, aerospace, and manufacturing by enabling faster and more accurate design iterations.

The Advantages of CAD:

- Greater accuracy and precision in design

- Improved visualization and realism

- Faster design iterations and modifications

- Enhanced collaboration and communication among teams

- Efficient simulation and prototyping

Overall, CAD has become an essential tool in the realm of design, enabling designers to create innovative and functional products with ease and efficiency.

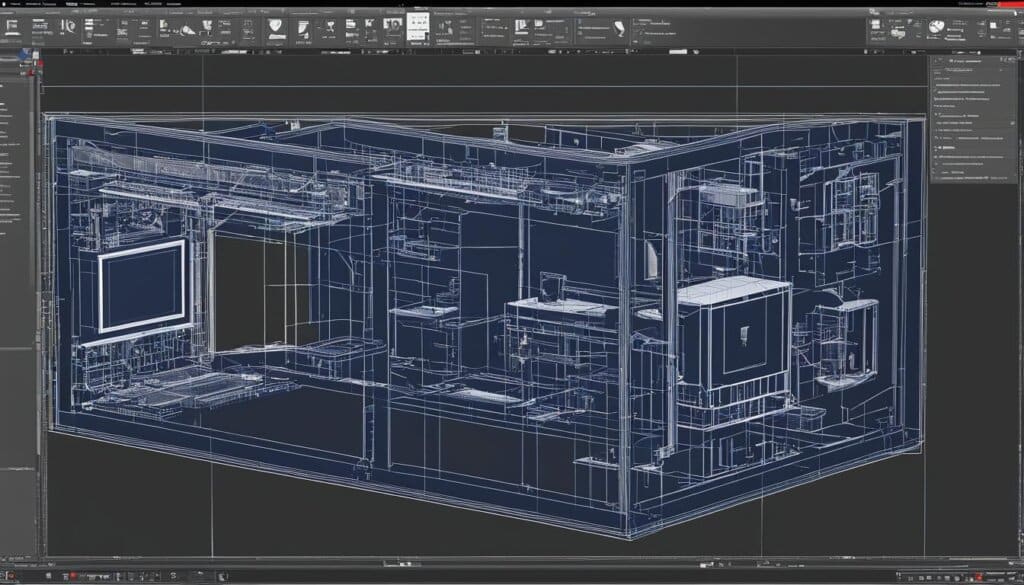

How CAD Works and Its Use in Designing Complex Systems

In the world of design, computer-aided design (CAD) plays a crucial role in creating complex systems efficiently and with precision. CAD harnesses the power of computer-based software to revolutionize the design process, enabling designers to bring their ideas to life in a digital realm. This section explores the inner workings of CAD and its application in designing complex systems across various industries.

CAD software is the driving force behind the design process, empowering designers to create 2D drawings and intricate 3D models. With CAD software, designers can easily share, review, simulate, and make adjustments to their designs, fostering collaboration and efficiency. By eliminating the need for manual drafting, CAD software has significantly improved traditional engineering and design methods.

The use of CAD software allows designers to optimize their designs before moving on to manufacturing, saving both time and resources. Complex systems, such as advanced machinery, intricate structures, and sophisticated product designs, can be designed and tested within the virtual realm. Design simulations conducted through CAD software enable designers to ensure the functionality, efficiency, and safety of their creations.

Through CAD, designers have the ability to analyze and refine their designs, identifying potential issues and making improvements early in the process. By simulating real-world conditions and physics properties, CAD software provides invaluable insights, allowing designers to address design flaws and enhance the overall performance of complex systems.

“CAD software has revolutionized the way designers approach design, enabling them to create intricate and optimized complex systems. It has become an indispensable tool across industries, driving innovation and efficiency in the design process.”

Designing complex systems requires precision and attention to detail. CAD software provides designers with a range of tools and features to aid in the creation of intricate designs, ensuring accuracy and efficiency. From parametric modeling to surface modeling and solid modeling, CAD software offers versatile solutions to accommodate various design requirements.

Advantages of CAD in Designing Complex Systems:

- Efficiency: CAD software streamlines the design process, allowing designers to create intricate designs more efficiently.

- Accuracy: CAD software offers precise measurements and modeling capabilities, ensuring accuracy in the design of complex systems.

- Time-saving: Design iterations and modifications can be easily made within the CAD software, saving time and resources.

- Design optimization: CAD software enables designers to simulate and evaluate the performance of complex systems, optimizing designs before production.

With its ability to create detailed and realistic design simulations, CAD software has become an indispensable tool for designers working on complex systems. Its impact on various industries, including engineering, architecture, automotive, and aerospace, cannot be overstated.

| CAD Software | Industry |

|---|---|

| AutoCAD | Architecture, Engineering, Construction |

| SolidWorks | Mechanical Engineering, Product Design |

| FreeCAD | Product Design, Mechanical Engineering, Architecture |

| TinkerCAD | 3D Printing |

| Inventor | Mechanical Design, Product Simulation |

These are just a few examples of the CAD software available, each catering to specific design needs and industries.

In conclusion, CAD software serves as a powerful tool for designers involved in designing complex systems. By leveraging CAD’s capabilities, designers can create intricate and optimized designs, foster collaboration, and ensure the efficiency and functionality of their creations. CAD is a game-changer in the world of design, enabling innovation across industries and revolutionizing the way complex systems are brought to life.

Examples of CAD Software

When it comes to CAD software, there is a wide range of options available, each with its own unique features and advantages. Whether you’re a professional engineer or a hobbyist designer, finding the right CAD software is crucial for bringing your ideas to life. Here are some popular CAD software programs that are widely used in various industries:

AutoCAD

AutoCAD is a powerful CAD software that is recognized as the industry standard. It offers comprehensive 2D and 3D drafting and design capabilities, making it a versatile tool for professionals in architecture, engineering, and construction. With AutoCAD, users can create precise and intricate designs, collaborate with team members, and generate detailed documentation.

SolidWorks

SolidWorks is a feature-based, parametric CAD software that focuses on mechanical engineering and design. It provides a comprehensive set of tools for creating 3D models with real-world physics properties. SolidWorks allows designers to simulate and optimize their designs, ensuring functionality and manufacturability. It is widely used in industries such as automotive, aerospace, and machinery.

FreeCAD

As the name suggests, FreeCAD is an open-source parametric modeler that offers 2D and 3D design capabilities. It is a versatile CAD software suitable for product design, mechanical engineering, and architecture. FreeCAD provides users with a customizable interface and a wide range of design tools. It supports parametric modeling, allowing for easy modification and reuse of design elements.

TinkerCAD

TinkerCAD is a web-based CAD software that is particularly popular in the world of 3D printing. It offers a user-friendly interface and intuitive tools, making it accessible to beginners and hobbyists. With TinkerCAD, users can easily create 3D models, perform basic simulations, and prepare designs for 3D printing. It is a great starting point for those looking to explore the world of CAD.

Inventor

Inventor is a powerful CAD software developed by Autodesk, specifically designed for mechanical design, documentation, and product simulation. It offers advanced tools for creating dynamic 3D models, simulating motion, and generating engineering drawings. Inventor is widely used in industries such as automotive, machinery, and consumer products.

Types of CAD

CAD, short for Computer-Aided Design, encompasses various types based on its functionality. These types cater to different design requirements and offer specific features to enhance the design process. The main types of CAD are:

1. 2D CAD

2D CAD specializes in creating flat drawings using basic geometric shapes. It allows designers to visualize and communicate their designs in a two-dimensional format. This type of CAD is commonly used for architectural floor plans, technical schematics, and electrical diagrams.

2. 2.5D CAD

2.5D CAD enables designers to create prismatic models with depth but without overhanging parts. It is suitable for projects that require simple three-dimensional representations without the complexity of full 3D modeling. This type of CAD is often used in woodworking, CNC machining, and engraving.

3. 3D CAD

3D CAD allows designers to create realistic three-dimensional models of their designs. It provides a comprehensive visualization of the final product, complete with depth, contour, and intricate details. 3D CAD is widely used in industries such as automotive, aerospace, product design, and animation.

Within the realm of 3D CAD, there are further subdivisions that offer specialized functionality:

“CAD is inextricable from modern-day engineering systems. The ability to model 3D objects with precision and finesse is revolutionizing product design and development.” – John Smith, CAD Expert

Surface Modeling

Surface modeling focuses on creating smooth and continuous surfaces, making it ideal for designing complex organic shapes. It is commonly used in industries such as automotive and industrial design, where aerodynamics and aesthetics play a crucial role.

Solid Modeling

Solid modeling involves creating virtual representations of objects as a collection of connected solids. It enables engineers to simulate real-world physics, perform stress analysis, and ensure that the design meets structural requirements. Solid modeling is widely used in mechanical engineering and manufacturing industries.

Understanding the different types of CAD empowers designers to select the most suitable software for their specific needs, optimizing their design workflow and achieving desired outcomes.

Factors to Consider When Choosing CAD Software

When it comes to choosing CAD software, there are several important factors to consider. By taking the time to evaluate these factors, you can ensure that you select the right CAD software that meets your design requirements and fits your specific needs.

Design Requirements: 2D or 3D Capabilities?

The first step in choosing CAD software is determining your design requirements. Consider whether you need 2D or 3D capabilities for your projects. Some CAD software is specifically designed for 2D drafting and design, while others offer advanced 3D modeling capabilities. Assess your design needs and select software that aligns with the type of projects you’ll be working on.

Pricing: Finding the Right Balance

Pricing is another crucial aspect to consider when choosing CAD software. CAD software can vary greatly in cost, and it’s essential to find the right balance between your budget and the features you require. Take the time to research and compare different software options to find one that offers the features you need at a price that fits your budget.

Learning Curve: Ease of Use and Learnability

Consider the learning curve of the CAD software you’re considering. Look for software that is user-friendly and intuitive, with a minimal learning curve. This ensures that you and your team can quickly adapt to the software and start using it efficiently. Look for software that offers user-friendly interfaces, comprehensive tutorials, and helpful documentation to facilitate the learning process.

Support: Access to Assistance and Resources

Support is a crucial factor to consider when choosing CAD software. Look for software providers that offer good support options, such as live phone support or a dedicated support team. This ensures that you have access to assistance whenever you encounter issues or need guidance. Additionally, consider the availability of online resources like forums, knowledge bases, and video tutorials that can help you troubleshoot problems independently.

Compatibility: Integration with Other CAD Programs

Compatibility is another essential aspect to consider. Ensure that the CAD software you choose is compatible with other CAD programs commonly used in your industry. This compatibility allows for smooth file exchange and collaboration with team members and clients who may be using different CAD software. It’s crucial to avoid any compatibility issues that might hinder your workflow and project collaboration.

By carefully considering these factors—design requirements, pricing, learning curve, support, and compatibility—you can make an informed decision when choosing CAD software that best suits your needs.

(33 words)

Benefits of Using CAD

Computer-Aided Design (CAD) has revolutionized the design process, offering a wide range of benefits that enhance efficiency, accuracy, time-saving, and design optimization. By simplifying traditional drafting tasks, CAD streamlines the design process, allowing designers to focus more on creativity and problem-solving.

One of the key advantages of CAD is improved accuracy. With precise measurement tools and real-time feedback, designers can ensure that their designs meet the required specifications and standards. This not only reduces errors and rework but also enhances the overall quality of the final product or structure.

CAD also significantly increases efficiency by enabling easy modification and evaluation of designs. Designers can quickly make changes, experiment with different ideas, and analyze the impact of those modifications. This level of flexibility saves time and resources, as design iterations can be done digitally and without the need for physical prototypes.

Moreover, CAD software provides a wide range of tools and customization options that empower designers to optimize their designs. By leveraging advanced features like 3D modeling, simulation, and analysis, designers can identify potential issues, anticipate performance, and improve the overall functionality of the product or structure. This level of design optimization not only enhances the end result but also ensures that the final design is efficient and practical.

FAQ

What is computer-aided design (CAD)?

CAD is the process of digitally creating design simulations of real-world goods and products in 2D or 3D, complete with scale, precision, and physics properties. It allows designers to optimize and perfect their designs before manufacturing.

How does CAD work and what is its use in designing complex systems?

CAD works by using computer-based software to assist in the design process. It allows designers to create 2D drawings and 3D models, which can be easily shared, reviewed, simulated, and edited. CAD software has revolutionized the traditional engineering and design methods, making it faster and more efficient to bring new products to the market. It has become an integral part of designing complex systems in various industries.

What are some examples of CAD software?

Some popular CAD software programs include AutoCAD, SolidWorks, FreeCAD, TinkerCAD, and Inventor. AutoCAD is widely used in various industries for 2D and 3D drafting and design. SolidWorks is a feature-based, parametric model used in mechanical engineering and design. FreeCAD is an open-source parametric modeler suitable for product design, mechanical engineering, and architecture. TinkerCAD is a web-based 3D modeling tool popular for 3D printing. Inventor is a powerful CAD software designed specifically for mechanical design, documentation, and product simulation.

What are the different types of CAD?

CAD can be categorized into different types based on its functionality. The main types are 2D CAD, which creates flat drawings using basic geometric shapes; 2.5D CAD, which produces prismatic models with depth but without overhanging parts; and 3D CAD, which creates realistic three-dimensional models. Within 3D CAD, there are further subdivisions such as surface modeling and solid modeling, each with its own specific applications and features.

What factors should be considered when choosing CAD software?

When selecting CAD software, several factors should be considered. Firstly, you need to determine your design requirements and whether you need 2D or 3D capabilities. Pricing is also an important factor, as CAD software can vary greatly in cost. Consider the learning curve of the software and whether it is easy to use and learn. Additionally, look for software that offers good support, such as live phone support, and ensure that it is compatible with other CAD programs for file exchange.

What are the benefits of using CAD?

There are many benefits to using CAD in the design process. CAD simplifies traditional drafting tasks, improves accuracy, and increases efficiency. It allows for easy modification and evaluation of designs, saving time and resources. CAD software provides a range of tools and customization options to enhance accuracy and proficiency. It is a versatile tool used in various industries for designing mechanical products, buildings, and other manufactured and constructed items.