Table of Contents

Computer-Aided Design (CAD) software has revolutionized the way professionals in various industries approach product design. CAD allows for more accurate and precise design representations, replacing manual design drafting and enabling engineers to manipulate designs virtually. CAD programs have become foundational in construction, architecture, and engineering sectors, transforming these industries and the processes involved in complex project phases.

CAD software offers numerous benefits for product designers. From increased productivity and reduced errors to improved quality and effective communication, CAD software has become an essential tool in the design process. Its versatility and capabilities empower designers to unleash their creativity and transform ideas into successful, well-engineered products.

How CAD is Implemented in Different Professions

CAD, or Computer-Aided Design, is an essential tool integrated into various professions, serving distinct purposes in each field. Let’s explore how CAD implementation benefits different sectors:

In Architecture

In the architecture industry, CAD is extensively employed to streamline design processes and enhance productivity. Leading firms embrace Building Information Modeling (BIM) software like Revit, which allows architects to create accurate 3D models and collaborate effectively with other project team members. BIM software increases efficiency by eliminating manual errors and enabling real-time updates, resulting in seamless project delivery.

Architects can visualize complex designs more effectively and conduct virtual walkthroughs to identify potential issues, promoting accuracy and precision in the planning and execution phases.

In Industrial Design

Industrial designers heavily rely on CAD programs to visualize product components and predict functionality. CAD software enables designers to create detailed 3D models and run simulations to evaluate the product’s performance before manufacturing. By leveraging CAD, industrial designers can assess ergonomics, aesthetics, and feasibility, resulting in innovative and market-ready designs that meet consumer demands.

In Graphic Design

Graphic designers utilize 2D or 3D CAD software to bring their creative visions to life. CAD software allows graphic designers to design visual mockups, illustrations, and animations with precision and intricacy. Through CAD, designers can experiment with different layouts, colors, and textures, leading to visually captivating graphics that effectively communicate messages across various mediums.

In Engineering

CAD is an invaluable tool for engineers across multiple disciplines. Engineering professionals rely on CAD software to draft buildings, infrastructure components, circuits, mechanical items, medical devices, and manufacturing parts. By using CAD, engineers can create intricate designs, simulate real-world conditions, and test product performance. CAD software enables engineers to optimize designs, identify and rectify any potential issues, and ensure the efficiency and safety of their projects.

| Profession | Common CAD Implementations |

|---|---|

| Architecture | Building Information Modeling (BIM) software like Revit |

| Industrial Design | 3D CAD software for visualizing components and predicting functionality |

| Graphic Design | 2D or 3D CAD software for creating visual mockups and illustrations |

| Engineering | CAD software for drafting buildings, circuits, mechanical items, etc. |

Increased Productivity with CAD Software

CAD software is a powerful tool that significantly enhances productivity in the field of product design. By harnessing the capabilities of CAD software, designers are able to work more quickly, resulting in shorter project timelines and increased efficiency. This, in turn, leads to reduced production costs and faster turnaround times for product development.

One of the key advantages of CAD software is the ability to experiment with design concepts more efficiently. Designers can easily explore different iterations and variations of a product, allowing for quicker design iterations and faster decision-making processes. With CAD, designers can save drafts digitally, eliminating the need for manual drawing revisions and saving valuable time in the design process.

Moreover, CAD software enables designers to work more collaboratively and effectively with smaller teams. The intuitive features of CAD programs promote seamless communication and collaboration among team members, resulting in a faster design process and improved productivity. By streamlining communication and enabling real-time collaboration, CAD software facilitates a more agile and flexible approach to product improvement.

Benefits of Increased Productivity

- Accelerated production: The enhanced efficiency offered by CAD software allows for faster production of designs, enabling businesses to bring products to market more quickly.

- Cost reduction: By enabling designers to work more rapidly and accurately, CAD software helps minimize waste and reduces costs associated with design revisions and errors.

- Premium product creation: CAD software empowers designers to spend more time on the creative aspects of product development, resulting in the creation of innovative and high-quality products.

Overall, CAD software plays a crucial role in driving productivity and efficiency in the product design process. Its ability to accelerate design iterations, streamline collaboration, and save time and resources makes CAD software an indispensable tool for modern designers.

| Increased Productivity with CAD Software |

|---|

Reducing Errors with CAD Software

In the realm of product design, accuracy and precision are paramount. Mistakes in design can lead to costly errors during manufacturing and result in subpar products. However, CAD software offers a powerful solution to mitigate these risks and reduce errors in the design process.

CAD software streamlines the design workflow by automating tasks such as symbol placement and drawing storage. This automation eliminates the potential for human error that often arises from manual design drafting. By leveraging CAD software, professionals can focus on the creative aspects of design while the software handles the technicalities.

One of the key advantages of CAD software in error reduction is its ability to alert designers to potential mistakes. The software can detect design flaws or discrepancies, allowing professionals to make corrections before the design is finalized. This real-time feedback greatly minimizes the chances of design mistakes going unnoticed.

Another significant benefit of CAD software is the virtual testing capability it offers. Engineers can create virtual prototypes and perform thorough analyses before proceeding to physical manufacturing. This virtual testing enables the identification and resolution of potential issues early in the design process, saving both time and resources.

By eliminating the need for physical prototypes, CAD software reduces the risk of errors during manufacturing. Physical prototypes are often costly to produce and time-consuming to refine. With CAD, engineers can iterate through design changes quickly and easily, ensuring accuracy and minimizing errors before production begins.

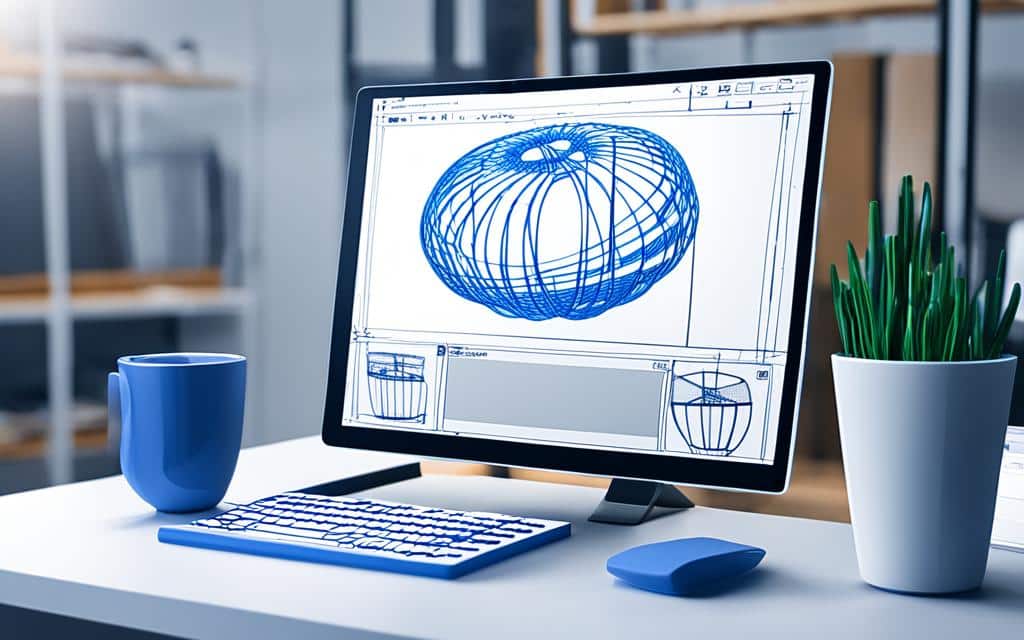

This image illustrates the concept of virtual testing, a feature enabled by CAD software. By conducting virtual tests and simulations, designers can identify and address potential design errors without the need for physical prototyping.

In conclusion, CAD software plays a vital role in reducing errors in product design. With its ability to automate tasks, detect potential mistakes, and facilitate virtual testing, CAD software empowers professionals to create designs with increased accuracy, efficiency, and confidence.

Improved Quality with CAD Software

CAD software plays a crucial role in enhancing the quality of product designs. By utilizing CAD software, designers can easily refer to previously saved drafts and designs, allowing them to detect and rectify potential errors at an early stage. This proactive approach ensures that construction commences with accurate and error-free designs, ultimately leading to higher quality outputs.

The use of CAD programs offers designers a wide range of design tools that aid in the meticulous consideration of calculations. These tools enable designers to conduct virtual investigations, simulating the functionality and performance of their designs before production. By conducting these virtual investigations, designers can identify and address potential flaws, ensuring that the final products meet the highest standards of design quality.

Furthermore, CAD software contributes to improved manufacturing speeds and reduced waste due to flawed designs. With precise design representation and thorough error prevention measures, CAD software allows for a more streamlined manufacturing process. This efficiency translates into faster production and minimizes the occurrence of design-related errors, resulting in cost savings and increased customer satisfaction.

Overall, CAD software empowers designers to produce designs of exceptional quality by providing them with the tools and capabilities to prevent errors and optimize their designs. The integration of CAD software in the product design workflow ensures that the final products represent the epitome of design excellence.

Benefits of Improved Quality with CAD Software

- Higher customer satisfaction due to improved design accuracy and functionality.

- Reduced manufacturing costs by minimizing design errors and waste.

- Faster time-to-market with streamlined production processes.

- Enhanced brand reputation through consistent delivery of high-quality products.

| Design Quality | Error Prevention | Virtual Investigation |

|---|---|---|

| Ensures designs meet highest standards | Identifies and rectifies potential errors | Simulates functionality and performance |

| Enhances customer satisfaction | Reduces manufacturing costs | Optimizes design before production |

| Improves brand reputation | Streamlines production processes | Minimizes design-related errors |

Effective Communication and Collaboration with CAD Software

CAD software plays a crucial role in enhancing communication and collaboration among team members working on product design projects. By improving the sharing of information, CAD software enables designers to work together more effectively, resulting in faster project completion and better outcomes. Let’s explore how CAD facilitates communication, collaboration, and information sharing in different aspects of the design process.

1. Sharing CAD Files and Remote Collaboration

Designers can easily share CAD files with their partners, regardless of their geographical location. This remote collaboration capability allows teams to work together seamlessly, eliminating the delays and challenges associated with physical transfer of design materials. By enabling real-time collaboration, CAD software accelerates decision-making, enhances productivity, and minimizes the risks of miscommunication and delays. Furthermore, remote collaboration reduces travel costs, enabling teams to allocate resources more efficiently.

2. Internal Information Sharing and B2B Interfacing

CAD software empowers organizations to foster better internal information sharing. Designers, engineers, and other stakeholders can access essential design files, drawings, and documentation, ensuring a smooth workflow and enabling effective cross-functional collaboration. This seamless sharing of information within an organization ensures alignment, eliminates redundant efforts, and enhances communication between departments.

In addition to internal information sharing, CAD software also facilitates business-to-business (B2B) interfacing. Companies can exchange CAD files with suppliers, contractors, and partners, allowing for better project coordination and minimizing the risk of misinterpretation and errors. By enabling consistent communication between different entities involved in the design process, CAD software streamlines collaboration, resulting in improved efficiency and reduced project timelines.

3. Interacting on the Assembly Line

Effective communication and collaboration are vital on the assembly line, where precision and efficiency determine the quality of the final product. CAD software enhances communication between designers and assembly line workers by providing clear visual representations of the design. Assembly line workers can refer to CAD models, drawings, and instructions, ensuring accurate implementation of design specifications. This reduces errors, rework, and delays, resulting in streamlined production processes and higher overall productivity.

4. Enhancing Customer Experience and Facilitating Marketing

With CAD software, designers can create realistic 3D models and visualizations of their products. These visual representations not only aid in the design process but also enhance the customer experience. Customers can visualize and interact with the virtual product before it is manufactured, enabling them to provide feedback and make informed decisions. Additionally, CAD software facilitates marketing efforts by providing high-quality visuals for catalogs, websites, and promotional materials.

“CAD software enables seamless collaboration, empowering designers to work together efficiently and unleash their innovation potential.”

Overall, CAD software revolutionizes communication and collaboration in product design projects. The ability to share CAD files, collaborate remotely, facilitate internal and B2B information sharing, enhance assembly line interaction, and create compelling 3D visualizations improves the efficiency and effectiveness of the entire design process. Designers and organizations that embrace CAD software position themselves for success, delivering innovative products and staying ahead in a competitive market.

Conclusion

CAD software has revolutionized the field of product design, offering a wide range of benefits for professionals across various industries. The integration of CAD technology has led to increased productivity, as designers can work more efficiently, resulting in faster design processes and reduced production costs. With CAD, teams can collaborate seamlessly, enabling effective communication and information sharing.

One of the key advantages of CAD software is its ability to reduce errors in product design. By automating tasks and providing real-time alerts, CAD minimizes the risk of design mistakes and human errors, ensuring accuracy and precision. Additionally, the software allows for virtual testing and quick prototyping, further enhancing the quality of designs and minimizing errors during manufacturing.

Beyond error reduction, CAD software improves the overall quality of product designs. Designers can easily reference saved drafts, make adjustments, and predict errors before construction begins. The advanced design tools provided by CAD software enable better calculations and considerations, resulting in higher-quality designs, improved manufacturing speeds, and reduced waste.

Embracing CAD technology empowers businesses to stay ahead in today’s competitive landscape. By leveraging CAD software, professionals in product design can unleash their creativity and transform ideas into successful, well-engineered products. CAD software has undoubtedly transformed the way products are designed, providing countless benefits to businesses and professionals alike.

FAQ

What is CAD software?

CAD software, or Computer-Aided Design software, is a tool that professionals use to create accurate and precise design representations. It allows for virtual manipulation of designs and has replaced manual design drafting in various industries.

How is CAD implemented in different professions?

CAD is integrated into various professions for different purposes. Architects use CAD extensively with building information modeling (BIM) software like Revit. Industrial designers utilize CAD programs to visualize components. Graphic designers use 2D or 3D CAD software to create visual mockups. Engineers leverage CAD for drafting buildings, infrastructure components, circuits, mechanical items, medical devices, and manufacturing parts.

How does CAD software increase productivity?

CAD software significantly enhances productivity by allowing designers to work more quickly, cutting production costs, and completing projects faster. It enables designers to experiment with design concepts efficiently and save drafts digitally. CAD also enables smaller teams to design more efficiently, create premium products, accelerate production, and be more flexible in product improvement.

How does CAD software reduce errors in product design?

CAD software automates tasks like symbol placement and drawing storage, reducing errors. It alerts professionals to potential mistakes and prevents human errors during the design process. CAD allows for quick prototyping and eliminates the need for physical prototypes, reducing the risk of errors during manufacturing. Engineers can easily make adjustments and changes in the design, ensuring accuracy and minimizing errors in production.

How does CAD software improve quality?

CAD software allows designers to address errors and improve quality by easily referencing saved drafts and designs. It enables designers to predict errors before construction begins, leading to higher quality designs. CAD programs offer a range of design tools that enhance the consideration of calculations, resulting in improved manufacturing speeds and reduced waste due to flawed designs.

How does CAD software facilitate communication and collaboration?

CAD software fosters better communication and collaboration by improving the sharing of information among team members. Designers can share CAD files with partners and collaborate remotely, allowing for faster completion of projects. CAD enables better internal information sharing, B2B interfacing, and interaction on the assembly line. 3D modeling and visualization also enhance the customer experience and facilitate marketing efforts.

What are the benefits of using CAD software for product design?

CAD software has revolutionized product design processes, providing numerous benefits to professionals in various industries. From increased productivity and reduced errors to improved quality and effective communication, CAD software allows designers to bring innovative products to market faster, reduce costs, and stay ahead in today’s competitive landscape. It empowers designers to unleash their creativity and transform ideas into successful, well-engineered products.