Table of Contents

American Wire Gauge (AWG) is the standard system used to denote wire size in North America. AWG is based on a numerical gauge scale, where the larger the number, the smaller the wire diameter and thickness. It was first introduced in 1857 as a way to standardize wire measurements and replace various measurements used by different manufacturers.

The largest standard size is 0000 AWG, while 40 AWG is the smallest standard size. AWG is primarily used to describe single-strand, solid, round, electrically conductive wire. It does not include the size of the insulation protecting the wire. The AWG size of a wire is important as it determines the amount of current the wire can safely carry. Decreasing the AWG size of a wire by three doubles its cross-sectional area and doubles its current carrying capacity.

Understanding AWG wire measurements is crucial when selecting the right wire size for various applications. Whether you are working on a DIY project or installing electrical systems in a commercial building, knowing the wire size is essential for proper functioning and safety.

What is AWG Wire and How Does It Work?

AWG wire, also known as American Wire Gauge, is a measurement standard used to determine the size and capacity of electrically conductive wire. The gauge number corresponds to the diameter of the wire, with larger gauge numbers representing smaller wire diameters.

The AWG scale operates on a logarithmic basis, where each AWG step is approximately 1.12293 times the change in diameter. This means that a smaller gauge (larger size) wire can safely conduct more electricity than a larger gauge (smaller size) wire.

Changing the AWG size by three doubles the cross-sectional area of the wire, which, in turn, doubles its current carrying capacity. This is an important consideration when selecting wire for different applications, as the wire needs to be able to safely handle the electrical load without overheating.

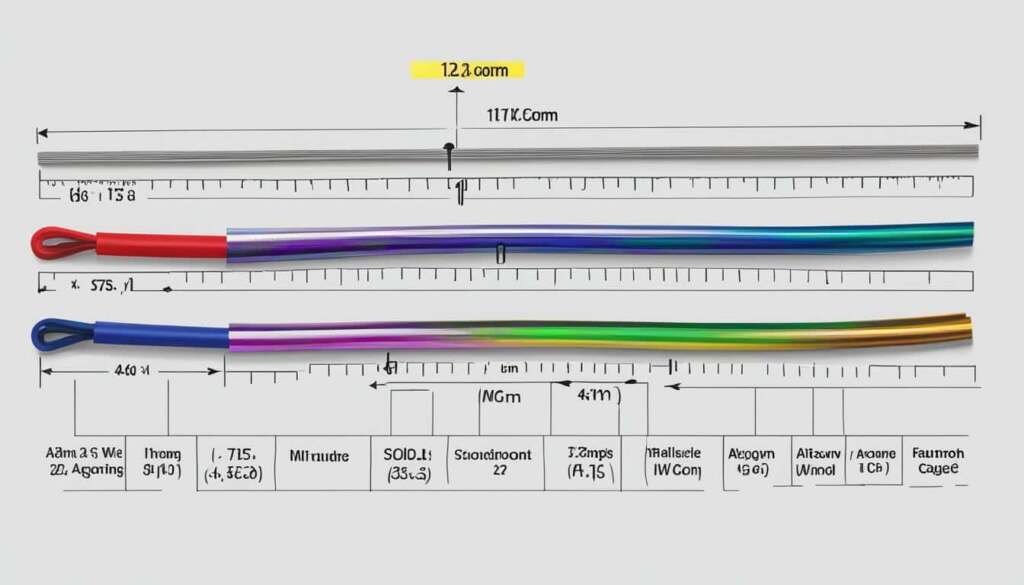

Here is a simplified visual representation of how changing the AWG size affects the cross-sectional area and current carrying capacity of a wire:

| AWG Size | Wire Diameter (inches) | Cross-Sectional Area (kcmil) | Current Carrying Capacity (Amps) |

|---|---|---|---|

| 12 | 0.0808 | 6532 | 20 |

| 10 | 0.1019 | 10380 | 30 |

| 8 | 0.1285 | 16510 | 50 |

| 6 | 0.1620 | 26240 | 65 |

As shown in the table above, decreasing the AWG size (from 12 to 10, for example) increases both the cross-sectional area of the wire and its current carrying capacity. This is because a smaller gauge wire has a larger diameter and therefore more space for electrons to flow through, resulting in a higher carrying capacity. It is crucial to consider the AWG size when designing electrical systems to ensure optimal performance and safety.

An image depicting the concept of AWG wire and its relationship with wire diameter, cross-sectional area, and current carrying capacity is provided below:

American Wire Gauge for Stranded Wire

When it comes to American Wire Gauge (AWG), it is primarily used to describe single-strand solid wire. However, in the case of multiple conductors or stranded wire, AWG refers to the equivalent single-strand cross-section in AWG of all the strands combined. This is essential in applications where flexibility and durability are required, as solid wire may be prone to breakage from bending or handling.

In the case of stranded wire, it is typically defined by three numbers: the AWG equivalent size, the number of strands, and the AWG size of each strand. For instance, a 23 AWG 5/30 stranded wire consists of five strands of 30 AWG, which collectively equal one 23 AWG wire.

This stranded design allows for enhanced flexibility while maintaining the desired cross-sectional area for the application. Stranded wire ensures better resistance to mechanical stress and offers improved conductivity compared to solid wire.

It’s important to select the appropriate AWG size for stranded wire to ensure the overall cross-sectional area meets the requirements of the specific application, ensuring optimal performance and safety.

Stranded wire offers numerous advantages in various industries, including automotive, aerospace, and electrical installations. Its increased flexibility and durability make it well-suited for applications that involve frequent movement or vibration.

Now that we understand how AWG applies to stranded wire, let’s explore the significance of American Wire Gauge in electrical wiring in the next section.

Importance of American Wire Gauge in Electrical Wiring

The American Wire Gauge (AWG) plays a vital role in electrical wiring, as it determines the current carrying capacity of a wire. Understanding the significance of AWG wire and wire gauge is crucial for safe and efficient electrical installations.

When it comes to wire gauge, the principle is simple: the larger the gauge number, the smaller the wire diameter, and the lower its current carrying capacity. Thicker wires with lower AWG numbers can safely handle more power without overheating.

Correctly choosing the AWG size for different wiring applications is essential. Whether you’re working on home or business electrical wiring, extension cords, or high-power wire in automotive or audio systems, selecting the appropriate AWG wire gauge is critical for both safety and performance.

Using a wire with a higher AWG number than required can lead to significant problems. Overheating, melting, and even fire hazards can result from using wires with inadequate current carrying capacity. It’s essential to understand the specific AWG wire gauge requirements for each application to ensure the electrical system operates safely and reliably.

Wire Gauge and Wiring Applications

Using the correct AWG wire gauge is crucial in electrical installations. Thicker wire sizes can handle higher electrical loads and prevent overheating, ensuring the safety and efficiency of the electrical system.

Here are some examples of common wire gauges used in different wiring applications:

| Wiring Application | Recommended AWG Wire Gauge |

|---|---|

| Low-voltage applications (thermostats, doorbells) | 18 AWG |

| Lighting circuits, bedroom, and office outlets | 14 AWG |

| Kitchens, bathrooms, and high-current devices | 12 AWG (20-amp outlets) |

| Electric ovens, air conditioning units | 8 AWG or 6 AWG |

| Networking, long cable runs | Thicker wire for Power over Ethernet (PoE) |

Choosing the right wire gauge ensures that the electrical system functions efficiently and safely, preventing potential hazards caused by inadequate wire sizes.

It’s worth noting that thicker wire sizes are typically more expensive due to their increased use of metal. However, investing in the appropriate wire gauge for each application is a fundamental aspect of electrical safety and ensures that the system operates reliably for years to come.

Application of American Wire Gauge in Different Scenarios

Different AWG wire sizes find extensive use in various electrical applications. Understanding the appropriate wire size to use is crucial for ensuring safe and efficient electrical systems. Here are some common scenarios where different wire sizes are employed:

1. Low-voltage applications:

For low-voltage applications such as thermostats and doorbells, thinner gauge wires like 18 AWG are commonly used. These wires provide the necessary current capacity for these low-power devices.

2. Lighting circuits, bedroom, and office outlets:

In lighting circuits, as well as for typical bedroom and office outlets, 14 AWG wire is widely used. This size offers adequate current carrying capacity for lighting fixtures and standard electrical appliances found in these environments.

3. Kitchens, bathrooms, and high-current devices:

Areas like kitchens and bathrooms, which often host devices that draw more current, require 20-amp outlets with 12 AWG wire. The larger wire size accommodates the increased current demand and helps prevent overheating.

4. Larger loads and heavy appliances:

Larger loads such as electric ovens and air conditioning units require thicker wires with larger cross-sectional areas. Therefore, 8 AWG or 6 AWG wire may be necessary to supply the higher current needed by these power-hungry appliances.

5. Networking and Power over Ethernet:

In networking applications, especially for long cable runs and Power over Ethernet (PoE) installations, thicker wire sizes may be required. This ensures adequate power delivery and minimizes signal loss over extended distances.

When selecting the appropriate AWG wire size for any of these applications, it’s essential to consider the specific electrical requirements and expected load. Using an undersized wire can lead to overheating, voltage drops, and potential safety hazards, while using oversized wires can be costly and inefficient.

| AWG Size | Typical Applications |

|---|---|

| 18 | Thermostats, doorbells |

| 14 | Lighting circuits, bedroom and office outlets |

| 12 | Kitchens, bathrooms, high-current devices (20-amp outlets) |

| 8 or 6 | Large loads, electric ovens, air conditioning units |

| Thicker wire | Networking, long cable runs, Power over Ethernet |

It’s crucial to consult electrical codes and regulations, as well as seek professional advice, when determining the appropriate AWG wire size for any specific electrical installation.

Understanding Wire Gauges and their Technical Specs

Wire gauges, such as the American Wire Gauge (AWG), provide a standardized system for measuring the thickness of wires. The gauge number signifies the wire’s thickness, with higher numbers indicating thinner wires. However, wire gauges also offer valuable insights into various technical specifications, including diameter, cross-sectional area, feet per pound, resistance, and current capacity.

Thicker wires with lower gauge numbers have larger diameters, greater cross-sectional areas, and lower electrical resistance. This means they can handle higher current capacities. In contrast, thinner wires with higher gauge numbers have smaller diameters and higher electrical resistance, limiting their current carrying capabilities. By understanding wire gauges and their technical specs, electricians and technicians can precisely determine the appropriate wire size for different applications, taking into account specific electrical requirements and the anticipated load.

When selecting a wire for a specific purpose, considering wire gauges is essential. The appropriate wire gauge ensures that the wire can handle the required electrical current without overheating or causing safety hazards. For instance, a larger gauge wire is typically suitable for high-current applications like electric ovens or air conditioning units, while thinner gauge wires find use in low-voltage applications like thermostats or doorbells.

By familiarizing themselves with wire gauges, professionals can make informed decisions about wire thickness, electrical resistance, and current capacity. This knowledge empowers them to choose the right wire for each task, ensuring optimal electrical performance and safety.

FAQ

What is the American Wire Gauge (AWG) standard?

The American Wire Gauge (AWG) is the standard system used to denote wire size in North America. It is based on a numerical gauge scale, where the larger the number, the smaller the wire diameter and thickness.

When was the AWG standard introduced?

The AWG standard was first introduced in 1857 as a way to standardize wire measurements and replace various measurements used by different manufacturers.

What does the AWG size of a wire represent?

The AWG size of a wire represents the wire’s diameter and thickness. The larger the AWG number, the smaller the wire size.

Does the AWG size include the size of the insulation?

No, the AWG size of a wire does not include the size of the insulation protecting the wire. It only represents the size of the conductive wire itself.

How does the AWG size of a wire affect its current carrying capacity?

The AWG size of a wire is important as it determines the amount of current the wire can safely carry. Decreasing the AWG size by three doubles its cross-sectional area and doubles its current carrying capacity.

How does AWG apply to stranded wire?

When multiple conductors or stranded wire use AWG, it refers to the equivalent single-strand cross-section in AWG of all the strands combined. This is important to ensure the overall cross-sectional area meets the requirements of the application.

Why is the AWG size important in electrical wiring?

The AWG size is of primary importance in electrical wiring because it determines the current carrying capacity of a wire. Thicker wires with lower AWG numbers can safely carry more power without overheating.

What are some common applications of different AWG wire sizes?

Thinner gauge wires like 18 AWG are suitable for low-voltage applications such as thermostats and doorbells. Lighting circuits commonly use 14 AWG wire, while 20-amp outlets in kitchens and bathrooms require 12 AWG wire. Larger loads like electric ovens and air conditioning units may require 8 AWG or 6 AWG wire.

What are the technical specifications associated with wire gauges?

Wire gauges also reflect other technical specifications such as diameter, cross-sectional area, feet per pound, resistance, and current capacity. Thicker wires with lower gauge numbers have larger diameters, greater cross-sectional areas, fewer feet per pound, lower electrical resistance, and higher current carrying capacities.