Table of Contents

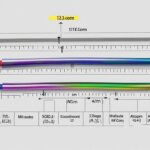

American Wire Gauge (AWG) is the standard system used in North America to denote wire size. It is a measurement of the wire’s diameter and thickness, with larger numbers representing smaller wire sizes. AWG is commonly used for single-strand, solid, round, electrically conductive wire. The largest standard size is 0000 AWG, and the smallest standard size is 40 AWG. AWG is important for determining the current-carrying capacity of a wire and ensuring electrical efficiency and safety in wiring. It is used in various applications, including home and business electrical wiring, extension cords, and automotive or audio wire. AWG size does not include the size of the insulation protecting the wire.

Understanding the concept of American Wire Gauge (AWG) is essential for anyone involved in electrical installations or repairs. It provides vital information about wire sizes, wire diameter, and electrical efficiency. By knowing the appropriate wire gauge for a particular application, you can ensure safe and efficient electrical connections.

In the following sections, we will explore the different aspects of AWG in more detail. We will discuss the implications of AWG for stranded wire, the importance of selecting the appropriate wire gauge, and the various wire sizes and their common uses.

What is AWG for stranded wire?

While American Wire Gauge (AWG) is primarily used to describe single-strand solid wire, it can also be applied to stranded wire. Stranded wire consists of multiple conductors, or strands, intertwined together. When determining the AWG size for stranded wire, it represents the equivalent single-strand cross-section of all the strands combined. This allows for a standardized measurement that simplifies wire gauge selection and compatibility.

For example, let’s consider a 23 AWG 5/30 stranded wire. This means it consists of five strands of 30 AWG wire that together have the equivalent cross-section of a single 23 AWG wire. The AWG size indicates the overall thickness of the stranded wire, taking into account the combined area of all the individual strands.

Stranded wire is commonly used in applications where flexibility and durability are important, such as automotive wiring or audio cables. The multiple conductors provide increased flexibility, making it easier to navigate around bends and corners. The strands also distribute the electrical current more evenly across the wire, reducing the risk of hotspots and improving overall electrical efficiency.

In addition, stranded wire offers enhanced mechanical strength, making it more resistant to breakage and fatigue compared to single-strand solid wire. This makes stranded wire suitable for applications that require frequent movement or vibration, as it can withstand the stress without compromising its performance.

| Advantages of AWG for stranded wire: | |||

|---|---|---|---|

| Flexibility | Durability | Improved electrical efficiency | Enhanced mechanical strength |

Overall, AWG provides a standardized measurement system that enables easy comparison and selection of stranded wire based on its electrical and mechanical properties. Whether in automotive, audio, or other applications where flexibility, durability, and optimal electrical performance are crucial, AWG is a valuable tool for determining the appropriate stranded wire size.

Stranded wire offers enhanced flexibility and durability compared to single-strand solid wire.

Importance of American Wire Gauge

The importance of American Wire Gauge (AWG) in electrical wiring cannot be overstated. This standardized system plays a pivotal role in determining wire resistance, current carrying capacity, and overall electrical power performance. By understanding the significance of wire gauge selection, professionals can ensure safe and efficient electrical installations.

One of the key factors impacted by wire gauge is wire resistance. Thicker wires with lower AWG numbers have less resistance, allowing for the smooth flow of current. This lower resistance translates to reduced heat generation and improved electrical efficiency. In contrast, thinner wires with higher AWG numbers can experience increased resistance, leading to higher temperatures and potential hazards.

The current carrying capacity of a wire is also heavily influenced by its gauge. Thicker wires can safely carry larger amounts of current without overheating, while thinner wires have limited capacity. Choosing the right wire gauge for a specific application is crucial to prevent wire failure, overheating, and even fires. For power-carrying wires, lower AWG numbers are generally preferred to ensure adequate current handling.

Aside from electrical performance, the selection of wire gauge also impacts the physical strength and cost of the wire. Larger gauge wires require more metal, making them stronger but also more expensive. Therefore, finding the right balance between wire gauge and desired physical attributes is essential when considering wire cost.

It’s important to note that while AWG is crucial for power-carrying wires, different wire requirements may apply for signal-carrying wires. These wires may prioritize other factors such as signal integrity and impedance matching. Consulting industry standards and guidelines is advised for signal wiring applications.

A Comparative Table of Wire Gauge and Current Carrying Capacity

| Wire Gauge (AWG) | Current Carrying Capacity |

|---|---|

| 12 | 20 Amps |

| 10 | 30 Amps |

| 8 | 40 Amps |

| 6 | 55 Amps |

The table above illustrates the current carrying capacity of wires with different AWG sizes. As wire gauge decreases, the current carrying capacity increases, allowing for the safe use of higher electrical loads.

Understanding the importance of American Wire Gauge (AWG) is vital for professionals in the electrical industry. By considering wire resistance, current carrying capacity, electrical power requirements, and wire cost, experts can select the appropriate wire gauge for each application, ensuring safety, efficiency, and optimal performance.

Wire Sizes and Their Uses

Different wire sizes have specific applications based on their current carrying capacity and other electrical properties. Understanding the appropriate wire size for each application is essential to ensure safety and optimal performance. Here are some common wire sizes and their uses:

– 18 AWG is typically used for low-voltage applications such as thermostats and doorbells, where a smaller wire size is sufficient.

– 14 AWG is commonly used for 15-amp lighting circuits, as well as bedroom and office outlets.

– 12 AWG is suitable for 20-amp outlets in kitchens, bathrooms, and areas with high-current devices.

– 10 AWG is used for 30-amp circuits that draw a significant amount of power, such as small electric ovens and washing machines.

– 8 AWG is employed for small ovens and air conditioning units that require a higher current capacity.

– 6 AWG is suitable for electric ovens and car chargers, where a heavier wire gauge is necessary to handle the electrical load.

These examples represent some of the most commonly used wire sizes. However, larger wire sizes such as 4 AWG and beyond are also available for even larger loads, like hot tubs and subpanels. The appropriate wire size depends on the specific application and the amount of current the wire needs to safely carry.

FAQ

What is AWG (American Wire Gauge)?

AWG is the standard system used in North America to denote wire size. It is a measurement of the wire’s diameter and thickness, with larger numbers representing smaller wire sizes.

What is the importance of AWG for determining wire size?

AWG is important for determining the current-carrying capacity of a wire and ensuring electrical efficiency and safety in wiring.

Can AWG be used to describe stranded wire?

Yes, AWG can be used to describe stranded wire. When multiple conductors are used in stranded wire, the AWG size represents the equivalent single-strand cross-section of all the strands combined.

Why is American Wire Gauge important?

The importance of American Wire Gauge lies in its impact on wire resistance and current carrying capacity. Thicker wires with lower AWG numbers have less resistance and can safely carry more current without overheating.

How do different wire sizes determine their uses?

Different wire sizes have specific applications based on their current carrying capacity and other electrical properties. For example, 18 AWG is typically used for low-voltage applications like thermostats and doorbells, while larger wire sizes like 4 AWG and beyond are used for even larger loads like hot tubs and subpanels.